HDPE cevni stroj

QINGDAO COMRISE MACHINERY CO., LTD.

Our main product is HDPE Pipe Machine

The main products are popular in the domestic market, such as the East China market, Southwest market, Northeast market, Central China market, etc. The products are also exported to international markets, including Russia, Australia, Southeast Asia, the Middle East, and Eastern Europe. Africa and other country.

Pe pipe

Good hygiene performance: During the processing of PE pipes, no heavy metal salt stabilizers are added, the material is non-toxic, there is no scaling layer, and there is no bacterial growth, which solves the hidden danger of secondary pollution of urban drinking water.

Excellent corrosion resistance: except for a few strong oxidants, it can withstand corrosion from various chemical media; No electrochemical corrosion.

Long service life: PE pipes can be safely used for more than 50 years at rated temperature and pressure.

Better impact resistance: PE pipes have good toughness, high impact resistance, and can withstand heavy objects directly passing through the pipeline will not cause the pipeline to rupture.

Similer Product

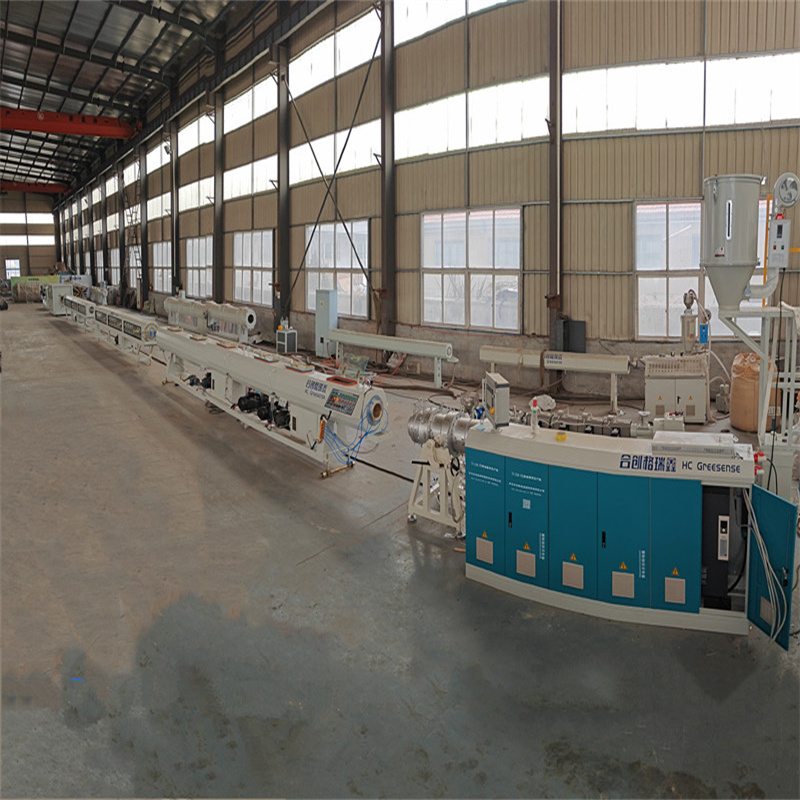

The PE (Polyethylene) pipe machine is a specialized piece of equipment designed for the production of polyethylene pipes. These pipes are widely used in various applications, including water supply, gas distribution, irrigation, and drainage systems. The PE pipe machine consists of several key components that work together to ensure efficient and high-quality pipe production.

ApplicationsWater Supply Systems: Municipal water distribution networks, residential and commercial water supply lines.

Gas Distribution: Natural gas pipelines, propane distribution systems.

Irrigation Systems: Agricultural irrigation, landscaping, and golf course watering systems.

Drainage Systems: Stormwater management, sewage systems, and industrial drainage.

Specifiation Parameters

(1)ExtruderFunction:

The extruder is responsible for melting and extruding the polyethylene pellets into a continuous tube.

Features: High torque drive system, precision temperature control, and efficient screw design for optimal material

processing.

Longth ratio L / D :33:1

Material quality: 38CrMoAlA

Siemens motor

ABB inverter

Siemens PLC computer control panel

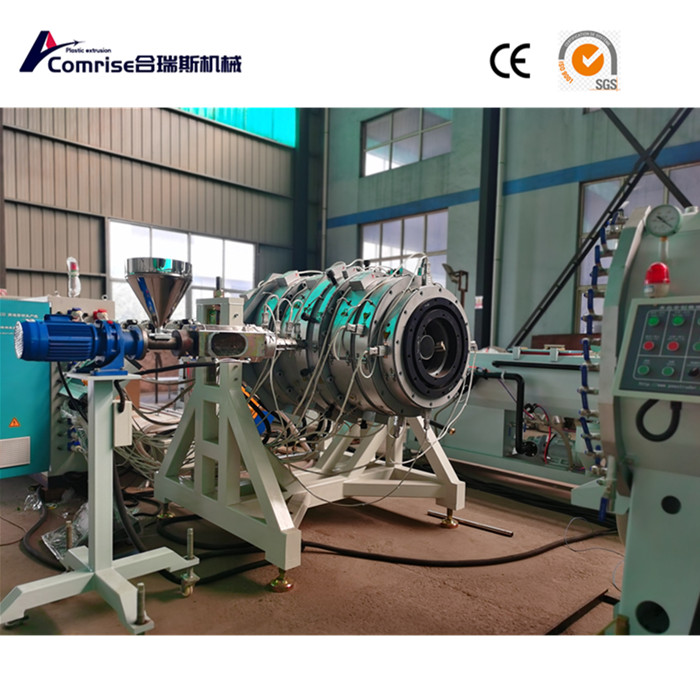

(2)New technology die head

The extrusion die adopts spriral structure to ensure uniform melt temperature, completely eliminate weld lines, overcome the stripe defect caused by blue die, and produce pipe products with smooth inner and outer walls and good compactness.

Pressure grades: as to customer table

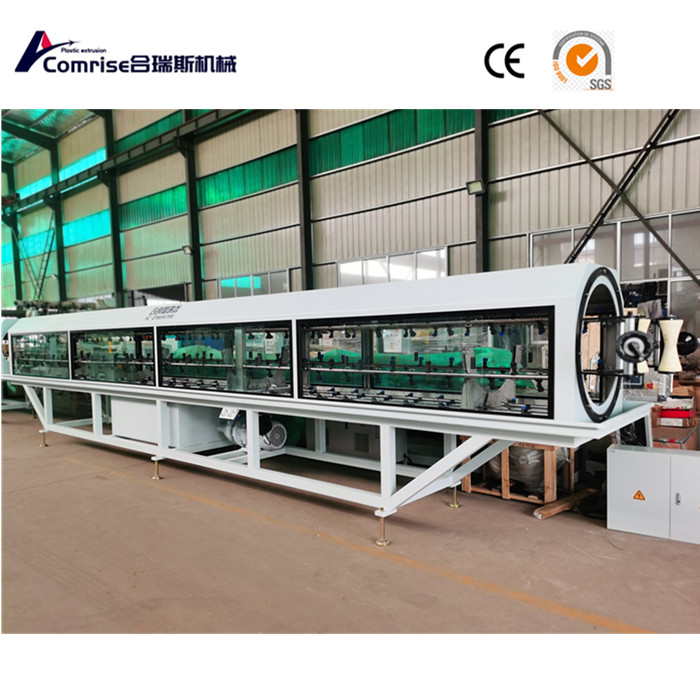

(3)Vacuum sizing water tankFunction:

The cooling system rapidly cools the extruded pipe to maintain its shape and structural integrity.

Features: Multi-stage cooling tanks with adjustable water flow rates and temperature control to ensure consistent cooling.

vacuum pump:3 + 4 KW, 2 sets

Water pump: 3 + 4 KW, 2 sets

Tank material: 100% Stainless steel

Length: 6000 mm

(4)Spray water tank

Water pump : 4 KW * 1 set

Water tank material:stainless steel

Length : 6000mm

Over all size :6500×500×1300mm

(5)Halling off machine:

The traction device is designed to be able to pull the pipe in a continuous and stable state. Its compact structure, maintenance-free structure and absolute balance of operation are its outstanding features.

Clamping way:claw pneumatic

Traction speed:1-15m/min

Pulling motor:motor 1.5KW x 2

Mode of speed regulation:Frequency Control

(6)Cutting machine:

Cutting method:Rotary cutting with circular blade

Clamping way:Pneumatic clamp

Worktable movement way: Synchronous follow up, pneumatic reset

Revolution motor power:1.5KW

Method of electric control : Independent setting of high-speed counter and PLC linkage

(7)Double station winding machine

The winding machine is used for small-sized 20-63mm PP PE PPR HDPE LDPE pipes. High winding efficiency

(8)Auto stocker

Stacker used for big size pipe.

About Us

High Production Efficiency:

Advanced extrusion technology ensures high output and consistent quality.

Automated control systems for precise operation and reduced labor costs.

Versatile Material Handling:

Capable of processing a wide range of polyethylene grades, including HDPE, MDPE, and LDPE.

Flexible production settings to accommodate different pipe diameters and wall thicknesses.

User-Friendly Interface:

Intuitive control panel with touch screen display for easy operation and monitoring.

Real-time data tracking and production statistics for better process control.

Robust Construction:

Heavy-duty frame and components for durability and long service life.

Low maintenance requirements and easy access for routine servicing.

Environmental Compliance:

Energy-efficient design to reduce power consumption and operating costs.

Minimal waste generation and recycling options for sustainable production.

GET A QUOTATION NOW

- View as

110 mm HDPE cevni stroj

Tovarniška tovarna 110 mm HDPE cevi stroj Machine Konfiguracija Manfacture je različna glede na območje premera cevi. Za območje majhnega premera, kot je 20-63 mm, obstaja več različnih modelov hitrosti za možnost, najvišja hitrost proizvodnje je do 60m/min za 20 × 2,0 mm HDPE cevi. Linija ekstruzij cevi z velikim premerom HDPE je mogoče oblikovati kot dvoslojna koekstruzijska vrsta ali 3 sloj koekstruzijski tip. Cevi Coiler je opremljen kot možnost, da se naliva velikost cevi od 16-32 mm ali 20-63 mm ali veliko velik do 110 mm.

Preberi večPošlji povpraševanjeVeliki premer PE cevi za proizvodnjo stroja

Stroji za stroje Stroji Tovarniški velik premer PE cevi za proizvodnjo cevi, ki jo proizvaja ta črta, ima značilnosti odlične togosti, gibčnosti, toplotne odpornosti, odpornosti na staranje, visoke mehanske trdnosti, odpornosti razpok okoljskega stresa, odpornosti na deformacijo lezenja, korozijsko odpornost in toplotno povezavo in tako naprej.

Preberi večPošlji povpraševanjeTri sloj HDPE CO Extrusion Cevi strojna linija

Cevi za vodje PE se običajno uporabljajo za mestno oskrbo z vodo, prevoz zemeljskega plina in plina, prehrambeno in kemično industrijo, prevoz rude in blata, zamenjavo cementnih cevi, cevi iz litega železa in jeklene cevi. China Factory 315-630 mm Tri sloj cena cena za cev za ekstruzijsko cev. PPR cevi se pogosto uporabljajo na poljih za oskrbo in drenažo vode, mestno in podeželsko vodo, urbani plin, električno energijo in vlaknasti optični kabelski plašč, pa tudi v gradbeništvu, občinskem, industrijskem in kmetijskem sektorju, prevozu industrijske tekočine ter kmetijskega namakanja.

Preberi večPošlji povpraševanjeHDPE cevni proizvodni stroj

Stroj za proizvodnjo cevi HDPE HDPE se uporablja predvsem za proizvodnjo oskrbe z vodo in odtočnimi cevmi v kmetijstvu, gradbeništvu in drugih poljih.315-630 mm dobavitelj proizvodne linije HDPE cevi Ta stroj je sestavljen iz ekstruderja, kalupa, vakuumskega kalibracijskega rezervoarja in vlečne naprave. Rezalna enota, zlomenik Stacker in druge posamezne enote Vijačna ekstruder in vlečna naprava sta opremljena z dobro znanimi napravami za regulacijo hitrosti s spremenljivo frekvenco, vakuumska črpalka in vodna črpalka pa sta iz znanih blagovnih znamk. Vlečne naprave vključujejo dva kremplje, tri kremplje, štiri kremplje, šest krempljev, osem krempljev, deset krempljev, dvanajst krempljev itd. Uporabite lahko rezalni stroji brez prahu, rezalni stroji za rezilo ali planetarni stroji za rezanje in zmogljivost enote je zanesljiva.

Preberi večPošlji povpraševanjeHDPE Extresions Line

Komor je vodilna Kitajska linija za iztiskanje cevi 110-315 HDPE. Na obstoječe čiste PE cevi zavijte več plasti ali plasti visoko trdnih vlaken, kot so steklena vlakna in poliestrska vlakna, da bodo cevi delovale , 110-315 linije za ekstruziranje cevi HDPE. Tlak se je povečal na 4MPa. Celotna proizvodna linija se samodejno nadzira s PLC od zamenjave materiala do zlaganja, kar zagotavlja zanesljivost Visok, enostaven za vzdrževanje. Izjemna značilnost te proizvodne linije je, da ne more proizvajati samo čistih PE cevi, ki ustrezajo mednarodnim standardom. Izdelava lahko tudi jeklene žice, ojačene s kompozitnimi plastičnimi cevmi.

Preberi večPošlji povpraševanjeHDPE cevi za proizvodnjo stroja

STROJ EXTRESION HDPE cevi za proizvodnjo cevi lahko uporabimo za proizvodnjo cevi PE različnih premerov, z odlično togostjo in prožnostjo, toplotno odpornostjo, odpornostjo na staranje, visoko mehansko močjo, odpornostjo na okolje, odpornost na okolje, odpornost na lezenje, toplotno vezjo, ki je bila tovarna Kitajska itd., Kitajska proizvodna linija in popravljala za plin, voda in pobralažirajo se za plin, voda in kmetijska namakanja.

Preberi večPošlji povpraševanje