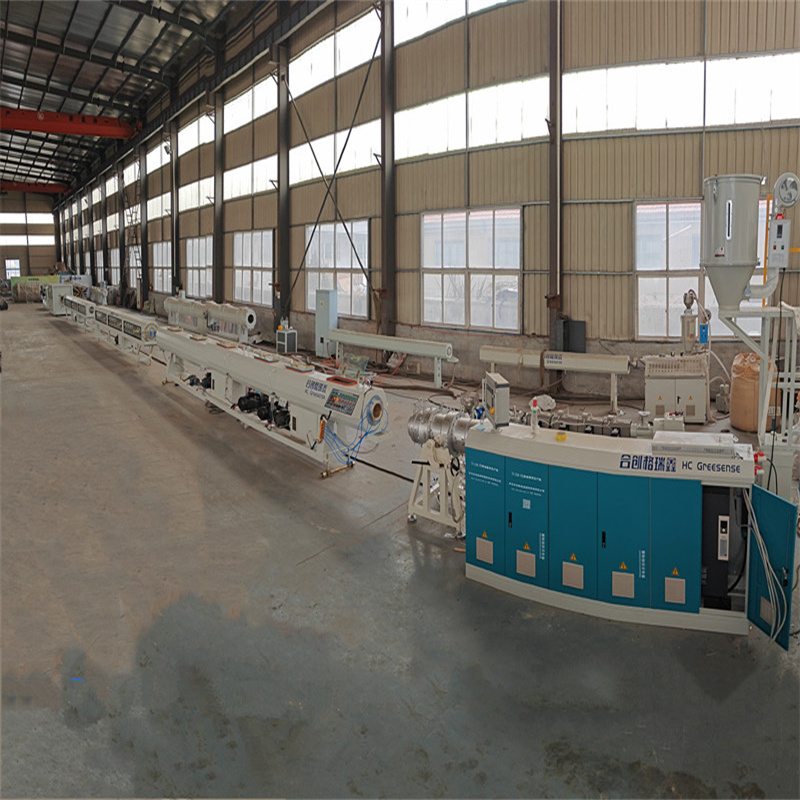

HDPE cevni stroj

QINGDAO COMRISE MACHINERY CO., LTD.

Our main product is HDPE Pipe Machine

The main products are popular in the domestic market, such as the East China market, Southwest market, Northeast market, Central China market, etc. The products are also exported to international markets, including Russia, Australia, Southeast Asia, the Middle East, and Eastern Europe. Africa and other country.

Pe pipe

Good hygiene performance: During the processing of PE pipes, no heavy metal salt stabilizers are added, the material is non-toxic, there is no scaling layer, and there is no bacterial growth, which solves the hidden danger of secondary pollution of urban drinking water.

Excellent corrosion resistance: except for a few strong oxidants, it can withstand corrosion from various chemical media; No electrochemical corrosion.

Long service life: PE pipes can be safely used for more than 50 years at rated temperature and pressure.

Better impact resistance: PE pipes have good toughness, high impact resistance, and can withstand heavy objects directly passing through the pipeline will not cause the pipeline to rupture.

Similer Product

The PE (Polyethylene) pipe machine is a specialized piece of equipment designed for the production of polyethylene pipes. These pipes are widely used in various applications, including water supply, gas distribution, irrigation, and drainage systems. The PE pipe machine consists of several key components that work together to ensure efficient and high-quality pipe production.

ApplicationsWater Supply Systems: Municipal water distribution networks, residential and commercial water supply lines.

Gas Distribution: Natural gas pipelines, propane distribution systems.

Irrigation Systems: Agricultural irrigation, landscaping, and golf course watering systems.

Drainage Systems: Stormwater management, sewage systems, and industrial drainage.

Specifiation Parameters

(1)ExtruderFunction:

The extruder is responsible for melting and extruding the polyethylene pellets into a continuous tube.

Features: High torque drive system, precision temperature control, and efficient screw design for optimal material

processing.

Longth ratio L / D :33:1

Material quality: 38CrMoAlA

Siemens motor

ABB inverter

Siemens PLC computer control panel

(2)New technology die head

The extrusion die adopts spriral structure to ensure uniform melt temperature, completely eliminate weld lines, overcome the stripe defect caused by blue die, and produce pipe products with smooth inner and outer walls and good compactness.

Pressure grades: as to customer table

(3)Vacuum sizing water tankFunction:

The cooling system rapidly cools the extruded pipe to maintain its shape and structural integrity.

Features: Multi-stage cooling tanks with adjustable water flow rates and temperature control to ensure consistent cooling.

vacuum pump:3 + 4 KW, 2 sets

Water pump: 3 + 4 KW, 2 sets

Tank material: 100% Stainless steel

Length: 6000 mm

(4)Spray water tank

Water pump : 4 KW * 1 set

Water tank material:stainless steel

Length : 6000mm

Over all size :6500×500×1300mm

(5)Halling off machine:

The traction device is designed to be able to pull the pipe in a continuous and stable state. Its compact structure, maintenance-free structure and absolute balance of operation are its outstanding features.

Clamping way:claw pneumatic

Traction speed:1-15m/min

Pulling motor:motor 1.5KW x 2

Mode of speed regulation:Frequency Control

(6)Cutting machine:

Cutting method:Rotary cutting with circular blade

Clamping way:Pneumatic clamp

Worktable movement way: Synchronous follow up, pneumatic reset

Revolution motor power:1.5KW

Method of electric control : Independent setting of high-speed counter and PLC linkage

(7)Double station winding machine

The winding machine is used for small-sized 20-63mm PP PE PPR HDPE LDPE pipes. High winding efficiency

(8)Auto stocker

Stacker used for big size pipe.

About Us

High Production Efficiency:

Advanced extrusion technology ensures high output and consistent quality.

Automated control systems for precise operation and reduced labor costs.

Versatile Material Handling:

Capable of processing a wide range of polyethylene grades, including HDPE, MDPE, and LDPE.

Flexible production settings to accommodate different pipe diameters and wall thicknesses.

User-Friendly Interface:

Intuitive control panel with touch screen display for easy operation and monitoring.

Real-time data tracking and production statistics for better process control.

Robust Construction:

Heavy-duty frame and components for durability and long service life.

Low maintenance requirements and easy access for routine servicing.

Environmental Compliance:

Energy-efficient design to reduce power consumption and operating costs.

Minimal waste generation and recycling options for sustainable production.

GET A QUOTATION NOW

- View as

HDPE cevi ekstrudiranja proizvodne linije

Stroj za proizvodnjo cevi HDPE, China Top Factory Factory Plastic Pipe Production Line, polipropilenska cev s to proizvodno linijo PE, lahko iztisnete kakovostne cevovodi za oskrbo z vodo in plinom z velikim premerom.20 mm-11mm-11mm HDPE Exusion Production Line Line Exture Production Line

Preberi večPošlji povpraševanjeHDPE Extrusion Production Line stroj

Stroj za proizvodnjo cevi HDPE cevi se uporablja predvsem v cevi za oskrbo z vodo in plinom. Smo zelo profesionalni dobavitelj strojev. Ta proizvodna linija lahko proizvede v cevi HDPE s premerom 110 mm, 125 mm, 160 mm, 200 mm, 250 in 315 mm, 110-315 mm proizvodno linijo za ekstruziranje cevi HDPE cevi in je lahko tudi primerna za proizvodnjo različnih cevi tlaka, ki so segale iz SDR9-SDR26.

Preberi večPošlji povpraševanjeABA Tri sloj Co Extrusion HDPE cevi

COMPISE Machine China Factory ABA Tri sloje CO Extrusion HDPE Cevi stroj je zasnovan predvsem za izdelavo cevi HDPE/PP, ki se cevi uporabljajo predvsem pri namakanju, oskrbi z vodo; Ekstruder lahko obdela zrnca PP/HDPE (tako deviško kot reciklirano, tudi s sestavljenim sestavljenim kredom). Izhod tega stroja lahko doseže približno 150-300kg/uro, za večino kupcev je priljubljena izbira.

Preberi večPošlji povpraševanjeHDPE cevi za proizvodnjo stroja

CMRISE Factory HDPE Pipe Machine Production Line sprejema najbolj vnaprejšnjo tehnologijo Evrope. Gre za nov raziskovalni dosežek energije - varčevanje proizvodnje Lin, ki je primeren za hitri ekstruziji HDPE, PP in drugih poliolefinskih cevi. V primerjavi s proizvodno linijo Cornmon se energetski varčevalni učinek doseže na 35%, učinkovitost izdelka pa se poveča za več kot 1 -krat, zato ne prihrani le stroškov mesta in delovne sile, ampak tudi izboljšuje učinkovitost. 110-135 mm HDPE Pipe stroj ima lep videz. Višja avtomatična stopnja, proizvodnja zanesljiva in stabilna.

Preberi večPošlji povpraševanjeHDPE ABA CO ekstruzijska proizvodna linija

Comrise factory HDPE ABA Co Extrusion Production Line can be used for HDPE large-diameter gas and PE water pipes, 110-315mm ABA Co extrusion production line,with excellent rigidity and flexibility, heat resistance, aging resistance, high mechanical strength, environmental stress crack resistance, creep deformation resistance, hot keys, etc. Therefore, this pipeline production line is the preferred gas and water pipe for urban and Primestni cevovodni sistemi in HDPE cevi velikega premera začenjajo igrati zelo pomembno vlogo v sistemih za oskrbo z vodo in plinom.

Preberi večPošlji povpraševanjeHDPE Pipe Machine Line

Zdravje izdelave HDPE Pipe Machine Line je specializiran kos opreme, zasnovan za proizvodnjo polietilenskih cevi. These pipes are widely used in various applications, including water supply, gas distribution, irrigation, and drainage systems. 20-50 mm HDPE cev je sestavljen iz več ključnih komponent, ki sodelujejo pri zagotavljanju učinkovite in kakovostne proizvodnje cevi

Preberi večPošlji povpraševanje